HBM Packaging Technology Divergence Explained: Understanding the Evolution of Modern Packaging Solutions

In the rapidly evolving world of manufacturing and logistics, packaging technology plays a critical role in ensuring product safety, efficiency, and sustainability. Among the various technological advancements in this domain, HBM Packaging Technology Divergence stands out as a notable development, offering innovative solutions that cater to different industries’ needs. This article will delve into HBM packaging technology divergence explained, discuss the key factors driving this divergence, and examine its implications for the future of packaging technology.

We’ll explore what makes HBM packaging technology unique, how it diverges from traditional methods, and the role of efficiency, sustainability, and scalability in its adoption.

What is HBM Packaging Technology?

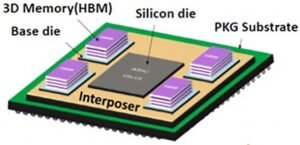

HBM packaging technology refers to a series of innovative packaging techniques designed to improve the way products are packed, stored, and transported. HBM stands for “High-Bandwidth Memory,” a technology that, while primarily associated with computing and semiconductor industries, has also inspired advances in packaging by emphasizing speed, compactness, and energy efficiency.

Over time, HBM packaging technology has evolved, creating distinct variations and methods tailored to different industries, from food and beverages to pharmaceuticals and electronics. Understanding the divergence in HBM packaging technology is crucial for companies aiming to remain competitive in an increasingly dynamic global market.

The Divergence of HBM Packaging Technology

1. Adaptation to Industry-Specific Needs

The first major factor behind the divergence in HBM packaging technology is its adaptation to industry-specific needs. Different industries require different packaging solutions based on product characteristics, storage conditions, and transportation requirements.

For example, in the pharmaceutical industry, packaging solutions need to prioritize tamper resistance, temperature control, and safe handling of delicate compounds. On the other hand, the food and beverage sector often focuses on packaging that extends shelf life, preserves freshness, and offers sustainable solutions.

As a result, HBM packaging technology has diverged into various subcategories, each with its unique design principles, materials, and functional characteristics. These divergent forms of HBM technology address the specific challenges posed by each industry, ensuring that the packaging is optimized for safety, efficiency, and cost-effectiveness.

2. Technological Advancements

The second significant driver of HBM packaging technology divergence is the rapid pace of technological advancements. New materials, automated processes, and digital integration have led to a departure from traditional packaging techniques, enabling more sophisticated, customizable solutions.

For instance, smart packaging solutions, such as RFID tags and QR codes, allow manufacturers to track shipments in real-time and monitor product conditions throughout the supply chain. HBM packaging technology has adapted to incorporate these technological features, providing value-added benefits like real-time monitoring and enhanced traceability.

Additionally, breakthroughs in sustainable materials—such as biodegradable plastics and recycled packaging components—have also influenced the divergence in HBM packaging technology. These advancements allow businesses to align their packaging solutions with environmental standards, a growing concern for consumers and regulatory bodies.

3. Scalability and Customization

Scalability is another aspect where HBM packaging technology has diverged from traditional methods. In industries like electronics, where the demand for compact and high-performance components is critical, HBM packaging technology has paved the way for scalable, space-efficient solutions.

Customization is equally important. Businesses are increasingly looking for packaging that reflects their brand identity while meeting functional requirements. Whether through specific design, color, or material choices, the customization options enabled by HBM packaging technology have contributed to its growing divergence.

The push for mass customization in packaging—where packaging is tailored for different customer segments or even individual customers—has further driven the split between standard packaging solutions and advanced, HBM-driven techniques.

4. Environmental Sustainability

Sustainability concerns have had a significant impact on the divergence of HBM packaging technology. According to a 2022 report by GlobalData, 74% of consumers are willing to pay more for sustainable packaging. This consumer demand has forced companies to adopt greener packaging practices, which are often enabled by HBM packaging technology’s ability to incorporate recyclable and eco-friendly materials.

In addition, the energy-efficient nature of HBM-inspired designs plays a vital role in reducing the carbon footprint of packaging processes. Traditional packaging technologies are often associated with high levels of waste and energy consumption, but HBM’s design principles promote more sustainable practices. As a result, companies are increasingly gravitating toward this technology to meet their sustainability goals.

5. Economic Factors and Cost-Effectiveness

Lastly, economic factors have contributed to the divergence in HBM packaging technology. As the cost of raw materials and labor continues to fluctuate, businesses are looking for packaging solutions that offer greater cost-efficiency without sacrificing quality. HBM technology’s compact and highly efficient designs enable businesses to reduce material waste and production costs, creating an economically viable option for both small and large-scale operations.

Furthermore, the scalability of HBM packaging technology allows companies to optimize their packaging processes based on volume. For large-scale manufacturers, this technology provides the flexibility to scale production up or down depending on demand, reducing operational costs and increasing efficiency.

The Impact of HBM Packaging Technology on Industry

The divergence of HBM packaging technology has had a significant impact on several industries, transforming the way products are packaged and distributed. For example:

- Pharmaceuticals: The incorporation of temperature-controlled, tamper-evident packaging helps ensure the safety and efficacy of medications.

- Food and Beverage: HBM packaging technology’s use of sustainable, biodegradable materials has significantly reduced the environmental impact of food packaging.

- Electronics: Compact, high-efficiency packaging allows for the safe transport of fragile and high-performance electronic components.

According to a 2023 report by Mordor Intelligence, the global packaging technology market is expected to reach a value of $1.2 trillion by 2028, driven largely by the increasing adoption of innovative technologies like HBM.

Stats and Data: How HBM Packaging Technology is Leading the Market

- Market Growth: The global packaging market has seen steady growth over the past decade, and HBM packaging technology is expected to account for a significant portion of this growth due to its flexibility, scalability, and sustainability features. According to Statista, the global packaging market was valued at $920 billion in 2021, with projected growth rates exceeding 4% annually.

- Consumer Preferences: Data from GlobalData shows that 74% of consumers prioritize sustainable packaging, and businesses adopting HBM technology have been able to align with this trend by incorporating eco-friendly materials into their packaging solutions.

- Cost-Reduction: A 2021 study by McKinsey & Company indicated that companies that have switched to more efficient packaging technologies like HBM report an average cost reduction of 15% in packaging materials and logistics expenses, making it a cost-effective solution for businesses of all sizes.

Conclusion

In summary, HBM packaging technology divergence represents the future of packaging solutions, offering industry-specific adaptability, advanced technological features, and sustainable practices that are essential for today’s global market. As businesses strive for efficiency, scalability, and sustainability, HBM packaging technology provides the versatility and innovation required to meet these needs.

Whether through cost-effectiveness, environmental responsibility, or cutting-edge digital features, HBM packaging technology continues to shape the evolution of modern packaging solutions. As the market for advanced packaging grows, will your business be ready to adapt to the future with HBM packaging technology?